1. Kukula

Bukuli limaphatikizapo magetsi oyendetsedwa ndi pneumatic, hydraulic opareshoni ndi mafuta-gasi olumikizidwa ndi flanged ma valve atatu opangidwa ndi trunnion mpira ndi mavavu omangika bwino a mpira okhala ndi kukula mwadzina NPS 8~36 & Gulu 300 ~ 2500.

2. Kufotokozera Kwazinthu

2.1 Zofunikira zaukadaulo

2.1.1 Design ndi kupanga muyezo: API 6D, ASME B16.34

2.1.2 Kutha mpaka kutha kwa kulumikizana: ASME B16.5

2.1.3 Muyezo wa nkhope ndi nkhope: ASME B16.10

2.1.4 Muyezo wa kalasi ya kuthamanga-kutentha: ASME B16.34

2.1.5 Kuyang'ana ndi kuyesa (kuphatikiza kuyesa kwa hydraulic): API 6D

2.1.6 Kuyesa kukana moto: API 607

2.1.7 Sulfur resistance processing ndi kuyang'anira zinthu (zogwiritsidwa ntchito ndi wowawasa): NACE MR0175/ISO 15156

2.1.8 Mayeso othawirako othawa (omwe angagwiritsidwe ntchito pautumiki wowawasa): malinga ndi BS EN ISO 15848-2 Kalasi B.

2.2 Kapangidwe ka valavu ya mpira

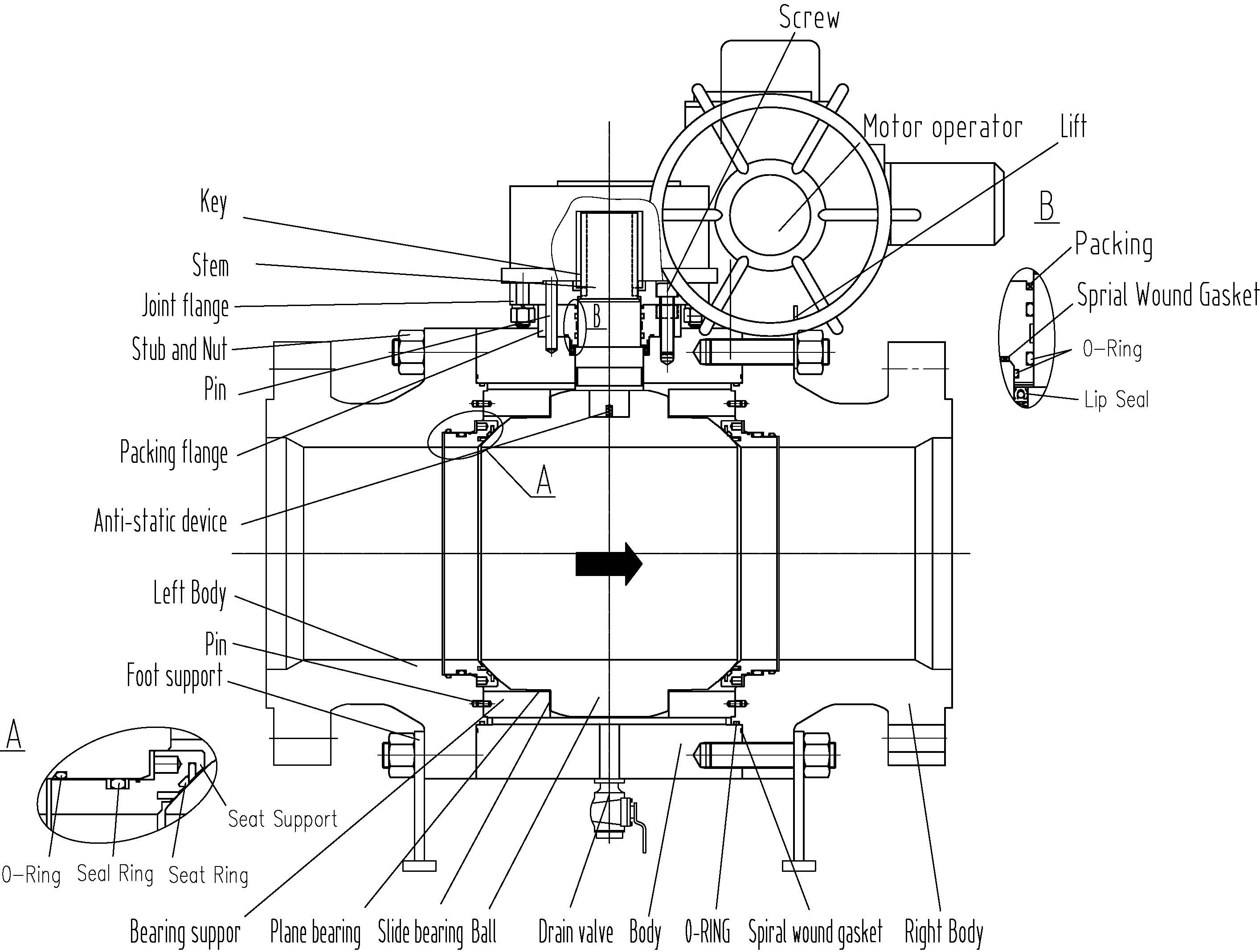

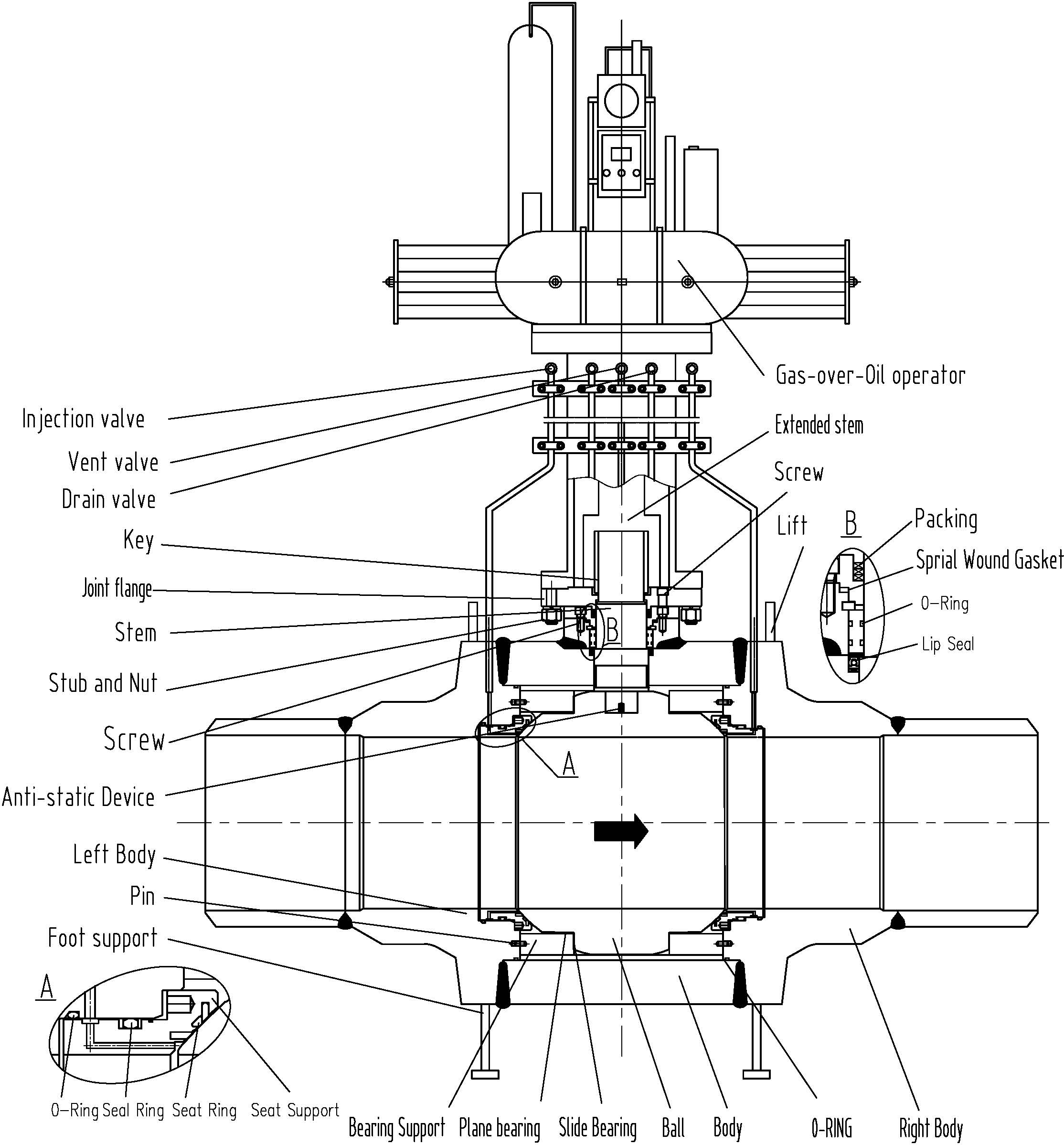

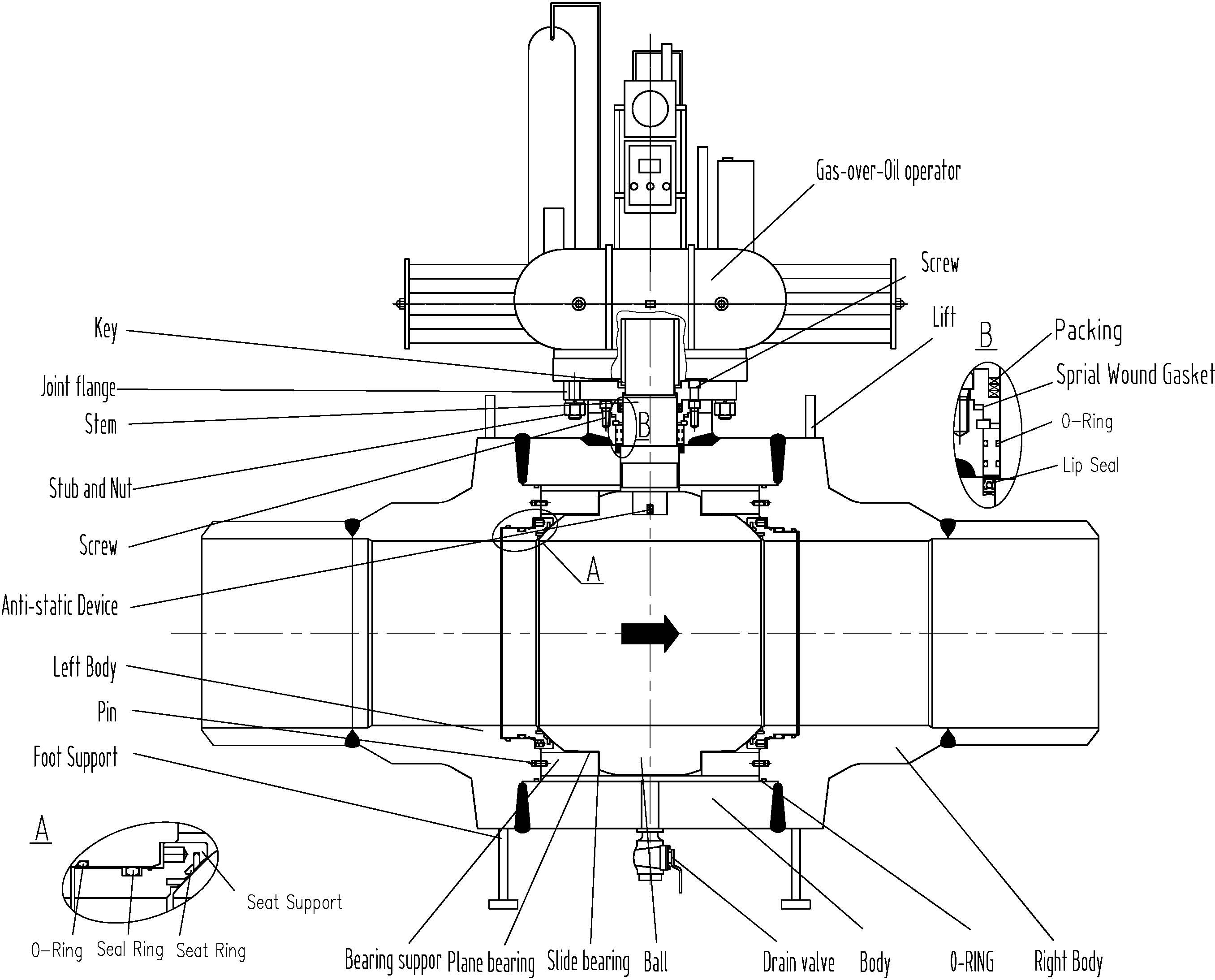

Chithunzi 1 Zidutswa zitatu zopangira ma valve a mpira wa trunnion okhala ndi magetsi

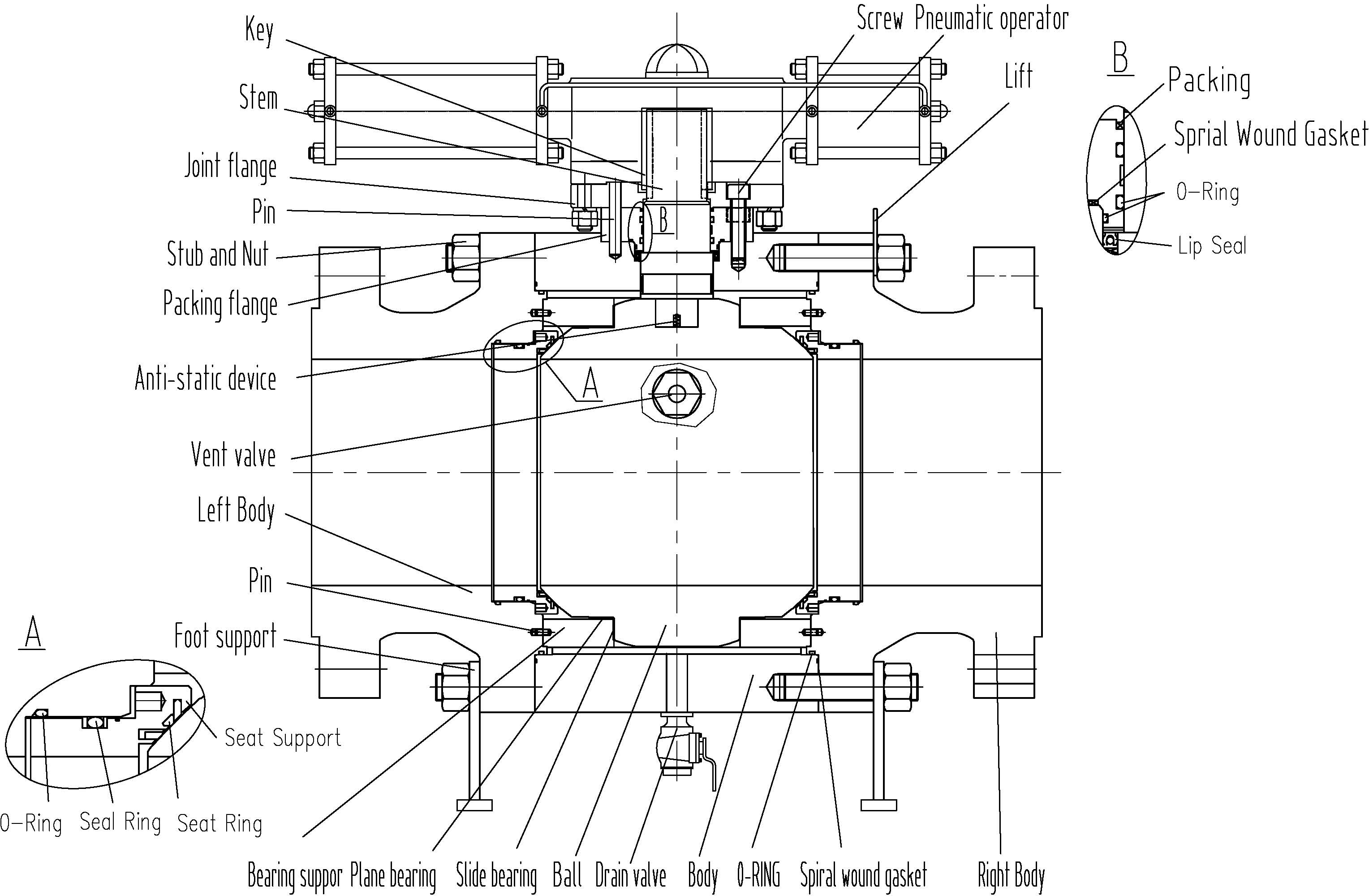

Chithunzi 2 Zidutswa zitatu zopanga mavavu a mpira wa trunnion okhala ndi mpweya

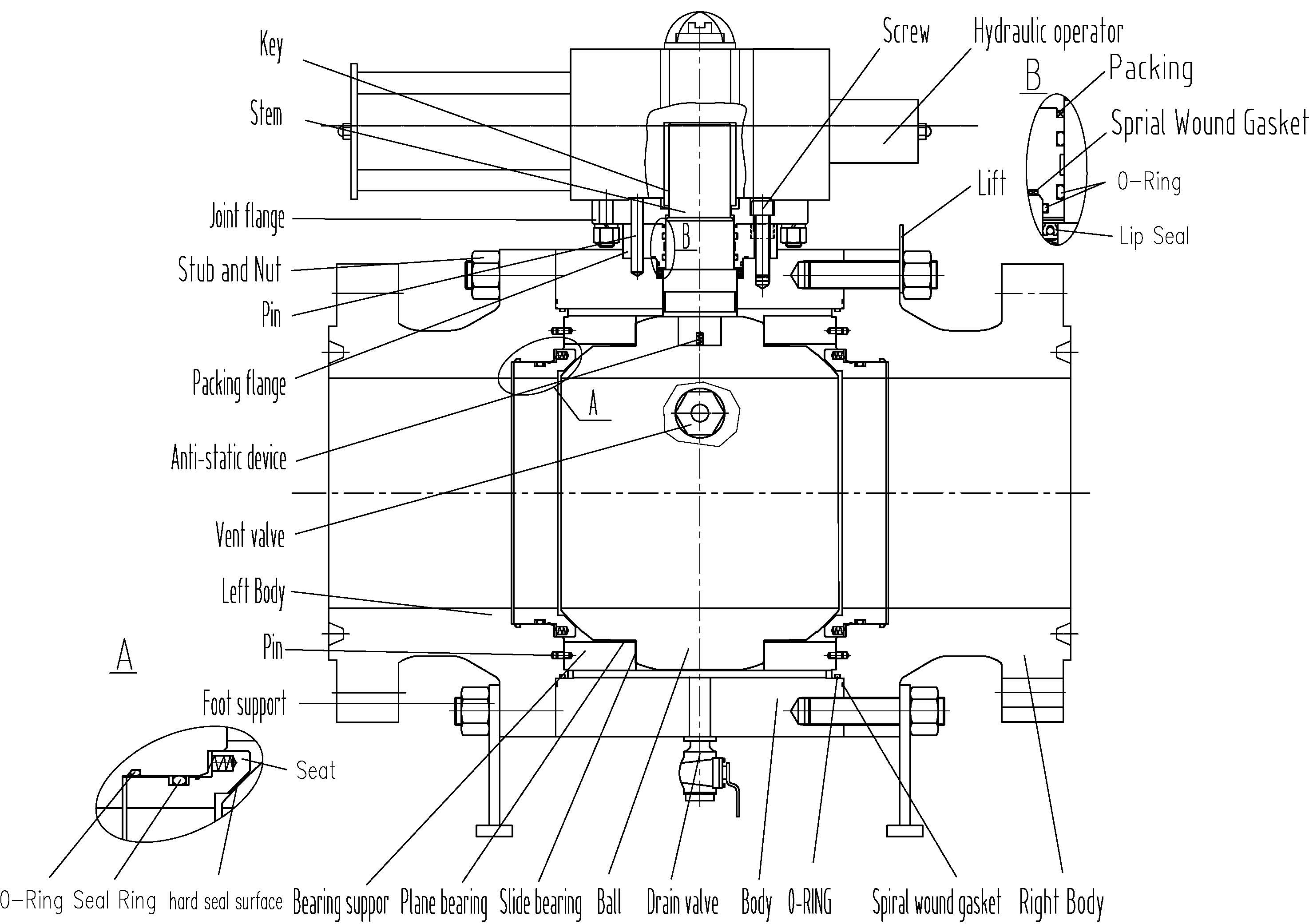

Chithunzi 3 Zidutswa zitatu zopangira ma valve a mpira wa trunnion okhala ndi ma hydraulic actuated

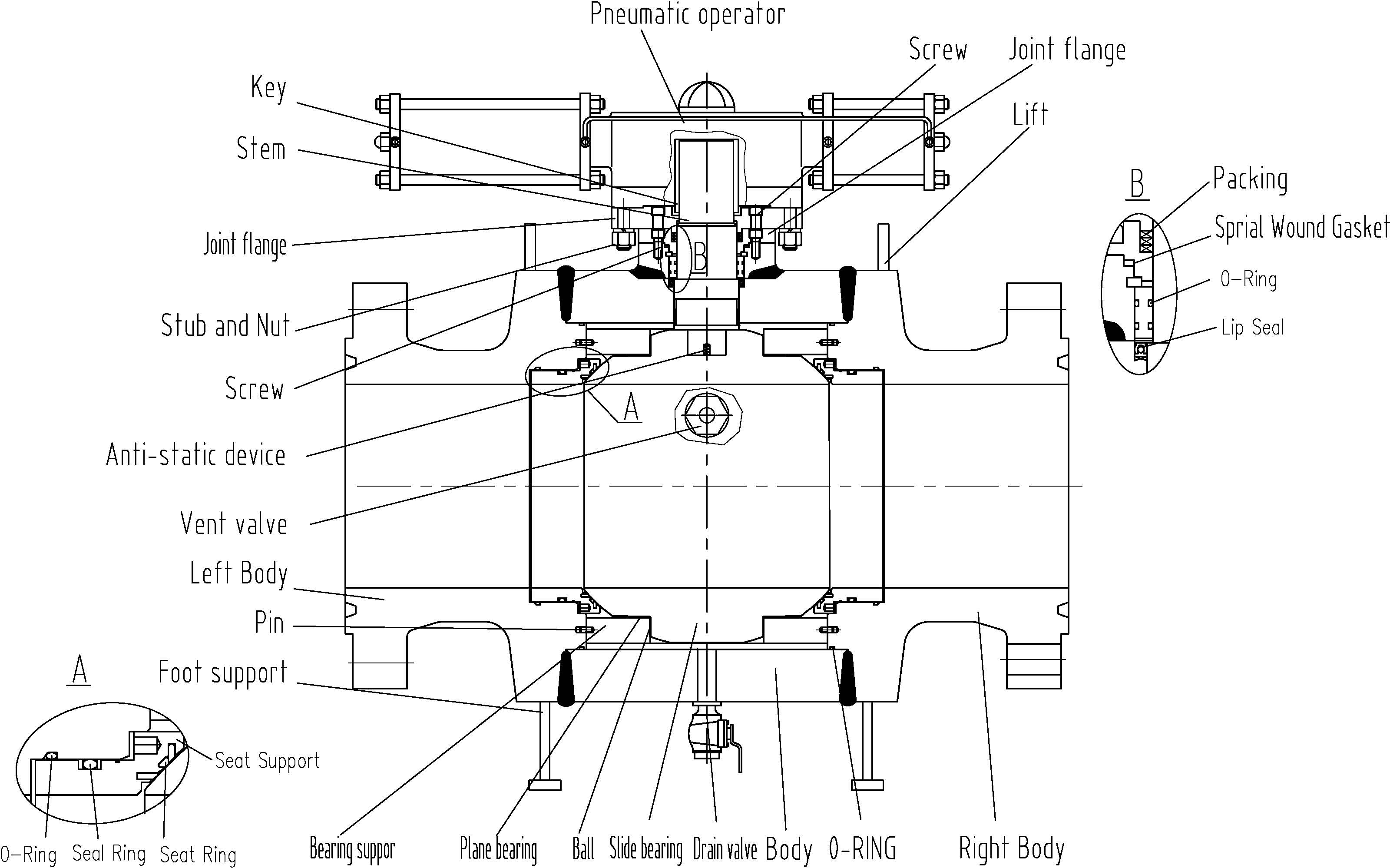

Chithunzi 4 Mavavu a mpira otsekedwa kwathunthu okhala ndi pneumatic actuated

Chithunzi 5 Anakwiriridwa mavavu a mpira otchingidwa kwathunthu ndi gasi woyendetsedwa ndi mafuta

Chithunzi 6 Mavavu a mpira otsekedwa kwathunthu okhala ndi gasi wamafuta

3. Kuyika

3.1 Kukonzekera koyambirira

(1) Mapaipi onse akumapeto a valve akonzeka.Kutsogolo ndi kumbuyo kwa mapaipi ayenera kukhala coaxial, ma flange awiri osindikizira ayenera kukhala ofanana.

(2) Mapaipi oyera, dothi lamafuta, zowotcherera, ndi zonyansa zina zonse ziyenera kuchotsedwa.

(3) Yang'anani chizindikiro cha valavu ya mpira kuti muzindikire mavavu a mpira omwe ali bwino.Vavu iyenera kutsegulidwa kwathunthu ndikutsekedwa kwathunthu kuti zitsimikizire kuti ikugwira ntchito bwino.

(4) Chotsani zida zodzitetezera polumikizana ndi mapeto onse a valve.

(5) Yang'anani kutseguka kwa valve ndikuyeretsa bwino.Nkhani yachilendo pakati pa mpando wa valve / mphete yapampando ndi mpira, ngakhale granule yokha ingawononge nkhope yosindikiza mpando wa valve.

(6) Musanakhazikitse, yang'anani mosamala nameplate kuti muwonetsetse kuti mtundu wa valavu, kukula kwake, zida zapampando ndi kalasi ya kutentha kwapaipi ndizoyenera momwe mapaipi amayendera.

(7) Musanakhazikitse, yang'anani ma bolts onse ndi mtedza polumikiza valavu kuti mutsimikizire kuti yalimba.

(8) Kuyenda mosamala mumayendedwe, kuponya kapena kuponya sikuloledwa.

3.2 Kuyika

(1) Vavu yoyikidwa paipi.Pazofunikira za ma media a valve, tsimikizirani kumtunda ndi kunsi kwa mtsinje molingana ndi momwe valavu iyenera kuyikidwira.

(2) Pakati pa valavu flange ndi payipi flange ayenera kuikidwa gaskets malinga ndi zofunikira pakupanga mapaipi.

(3) Maboliti a flange ayenera kukhala ofanana, motsatizana, olimba

(4) Mavavu olumikizira matako ayenera kukwaniritsa zofunikira izi akamatenthedwa kuti akhazikitsidwe pamapaipi pamalopo:

a.Kuwotcherera kuyenera kuchitidwa ndi wowotcherera yemwe ali ndi satifiketi yoyenerera yowotcherera yovomerezedwa ndi Boma la Boiler ndi Pressure Vessel Authority;kapena wowotcherera yemwe walandira satifiketi yoyenerera yowotcherera yomwe yafotokozedwa mu ASME Vol.Ⅸ.

b.Njira zowotcherera zowotcherera ziyenera kusankhidwa monga momwe zafotokozedwera m'buku lotsimikizira zazinthu zowotcherera

c.Kapangidwe kake, kachitidwe ka makina komanso kukana kwa dzimbiri kwa zitsulo zodzaza ndi zowotcherera zimayenera kugwirizana ndi chitsulo choyambira.

(5) Pokweza ndi lug kapena valve khosi ndi gulaye unyolo kumangirira pa dzanja gudumu, gear box kapena actuators ena saloledwa .

(6) Thupi la welded mpira valavu ndi kuchokera matako mapeto weld 3 "panthawi iliyonse kunja kwa Kutentha kutentha si upambana 200 ℃. Pamaso kuwotcherera, miyeso ayenera kumwedwa kupewa zonyansa monga kuwotcherera slag mu Kugwera mu ngalande ya thupi kapena kusindikiza pampando Paipi yomwe idatumiza chida chodziwira bwino chiyenera kutengedwa muyeso wa kuuma kwa weld Kulimba kwa msoko ndi zoyambira sizipitilira HRC22.

(7) Mukayika ma valve ndi ma actuators, mbali ya actuator nyongolotsi iyenera kukhala yolunjika kumtunda wa payipi.

3.3 Kuyang'ana pambuyo kukhazikitsa

(1) Kutsegula ndi kutseka nthawi 3 ~ 5 kwa ma valves a mpira ndi ma actuators sayenera kutsekedwa ndipo zimatsimikizira kuti ma valve amatha kugwira ntchito bwinobwino.

(2) Kulumikizana kwa nkhope ya flange pakati pa payipi ndi valavu ya mpira kuyenera kufufuzidwa momwe ntchito yosindikizira imayendera malinga ndi zofunikira za kapangidwe ka mapaipi.

(3) Pambuyo kukhazikitsa, kuyesa kuthamanga kwa dongosolo kapena mapaipi, valavu iyenera kukhala yotseguka kwathunthu.

4 .Kugwira ntchito, kusunga ndi kukonza

Vavu ya 4.1 ya mpira ndi 90 ° yotsegula ndi kutseka, valavu ya mpira imagwiritsidwa ntchito posintha ndipo siigwiritsidwa ntchito posintha!Sizololedwa kuti valavu yogwiritsidwa ntchito pamwamba pa kutentha ndi malire a kuthamanga ndi kusinthasintha pafupipafupi, kutentha ndi ntchito yogwiritsira ntchito.Kutentha kwapakati-kutentha kuzikhala molingana ndi ASME B16.34 Standard.Mabotiwo akhwimitsidwenso ngati atayikira pa kutentha kwakukulu.Osalola kukhudza kutsitsa ndipo chodabwitsa cha kupsinjika kwakukulu sikulola kuwonekera pa kutentha kochepa.Opanga amakhala opanda udindo ngati ngozi ichitika chifukwa chakuphwanya malamulo.

4.2 Wogwiritsa ntchito ayenera kudzaza mafuta opaka mafuta (mafuta) pafupipafupi ngati pali mavavu amtundu wa lubricant.Nthawi iyenera kukhazikitsidwa ndi wogwiritsa ntchito molingana ndi kuchuluka kwa ma valve otsegulira, nthawi zambiri kamodzi miyezi itatu iliyonse;ngati pali mavavu aliwonse omwe ali amtundu wa chisindikizo, mafuta osindikizira kapena kulongedza mofewa ayenera kudzazidwa panthawi yake ngati ogwiritsa ntchito apeza kutayikira, ndikuwonetsetsa kuti palibe kutayikira.Wogwiritsa ntchito nthawi zonse amakonza zida zili bwino!Ngati pali zovuta zina pa nthawi ya chitsimikizo (malinga ndi mgwirizano), wopanga ayenera kupita kumalo mwamsanga ndikuthetsa vutoli.Ngati nthawi yoposa chitsimikizo (malinga ndi mgwirizano), pamene wogwiritsa ntchito akufuna kuti tithetse vutoli, tidzapita kumalo mwamsanga ndikuthetsa vutoli.

4.3 Kuzungulira kozungulira kozungulira kwa mavavu opangira pamanja kudzatsekedwa ndipo kusinthasintha kwa ma valve opangira pamanja kudzatsegulidwa.Pamene njira zina, batani lowongolera bokosi ndi malangizo ayenera kukhala ogwirizana ndi kusintha kwa ma valve.Ndipo pewani ntchito yolakwika idzapewa kuchitika.Opanga sakhala ndi udindo chifukwa cha zolakwika zamagwiritsidwe ntchito.

4.4 Ma valve ayenera kukonzedwa nthawi zonse ma valve atagwiritsidwa ntchito.Nkhope yosindikizira ndi abrasion iyenera kufufuzidwa nthawi zambiri, monga ngati kunyamula ndikukalamba kapena kulephera;ngati thupi lichitika dzimbiri.Ngati zomwe tafotokozazi zichitika, ndi nthawi yake kukonzanso kapena kusintha.

4.5 Ngati sing'angayo ndi madzi kapena mafuta, akuti ma valve ayenera kuyang'aniridwa ndi kusamalidwa miyezi itatu iliyonse.Ndipo ngati sing'angayo ikuwononga, ndiye kuti ma valve onse kapena gawo limodzi la ma valve ayenera kuyang'aniridwa ndikusamalidwa mwezi uliwonse.

Vavu ya 4.6 ya mpira nthawi zambiri ilibe mawonekedwe otenthetsera kutentha.Pamene sing'anga ndi kutentha kwakukulu kapena kutentha kochepa, pamwamba pa valve siloledwa kukhudza kuti zisapse kapena kuzizira.

4.7 Pamwamba pa mavavu ndi tsinde ndi mbali zina zimaphimba mosavuta fumbi, mafuta ndi tizilombo toyambitsa matenda.Ndipo valavu iyenera kukhala yowonongeka ndi dzimbiri mosavuta;ngakhale izi zimachitika chifukwa cha kutentha kwamphamvu komwe kumayambitsa kuopsa kwa gasi wophulika.Chifukwa chake valavu iyenera kuyeretsa nthawi zambiri kuti iwonetsetse kuti ikugwira ntchito bwino.

4.8 Pamene kukonzanso ndi kukonza ma valve, mofanana ndi kukula koyambirira ndi ma o-mphete, ma gaskets, bolts ndi mtedza ziyenera kugwiritsidwa ntchito.O-mphete ndi gaskets mavavu angagwiritsidwe ntchito ngati kukonza ndi kukonza zida zosinthira mu dongosolo kugula.

4.9 Ndizoletsedwa kuchotsa mbale yolumikizira kuti ilowe m'malo mwa mabotolo, mtedza ndi o-mphete pamene valavu ili mumkhalidwe wopanikizika.Pambuyo pa zomangira, mabawuti, mtedza kapena mphete za o, ma valve amatha kugwiritsanso ntchito pambuyo poyesa kusindikiza.

4.10 Kawirikawiri, zigawo zamkati za ma valve ziyenera kusankhidwa kukonzanso ndikusintha, ndi bwino kugwiritsa ntchito zigawo za opanga kuti zisinthe.

4.11 Ma valve ayenera kusonkhanitsidwa ndi kusinthidwa pambuyo poti ma valve akonzedwa.Ndipo ayesedwe atasonkhanitsidwa.

4.12 Sitikulimbikitsidwa kuti wogwiritsa ntchito apitirize kukonza valve yokakamiza.Ngati zida zowongolera zokakamiza zakhala zikugwiritsidwa ntchito kwa nthawi yayitali, ndipo ngozi yomwe ingachitike idzachitika, ngakhale zimakhudza chitetezo cha wogwiritsa ntchito.Ogwiritsa alowe m'malo mwa valve yatsopano panthawi yake.

4.13 Malo owotcherera a ma valve owotcherera papaipi ndi oletsedwa kukonzedwa.

4.14 Mavavu papaipi saloledwa kugunda;ndi yoyenda basi, ndi ngati zolemera ziri zonse;

4.15 Mapeto ayenera kuphimbidwa ndi chishango m'chipinda chowuma ndi mpweya wabwino, kuti atsimikizire kuyera kwa valve.

4.16 Ma valve akuluakulu ayenera kukwezedwa ndipo sangathe kukhudzana ndi pansi pamene akusungira panja Komanso, kutetezedwa kwa chinyezi kumayenera kuzindikiridwa.

4.17 Pamene valavu yosungiramo nthawi yayitali ikugwiritsidwanso ntchito, kulongedza kuyenera kufufuzidwa ngati kuli kosayenera ndikudzaza mafuta odzola m'madera ozungulira.

4.18 Ntchito zogwirira ntchito za valve ziyenera kukhala zoyera, chifukwa zimatha kuwonjezera moyo wake wautumiki.

4.19 Valavu yosungiramo nthawi yayitali iyenera kuyang'aniridwa nthawi zonse ndikuchotsa dothi.Malo osindikizira ayenera kumvetsera kuti akhale oyera kuti asawonongeke.

4.20 Zolemba zoyambirira zimasungidwa;pamwamba mavavu, tsinde kutsinde ndi flange kusindikiza pamwamba flange ayenera kulabadira kuteteza.

4.21 Mphepete mwa ma valve saloledwa kukhetsa pamene kutsegula ndi kutseka sikufika pa malo osankhidwa.

5. Mavuto omwe angakhalepo, zoyambitsa ndi njira zothetsera (onani fomu 1)

Fomu 1 Mavuto omwe angakhalepo, zoyambitsa ndi njira zothetsera

| Kufotokozera zavuto | Chifukwa chotheka | Njira zowongolera |

| Kutayikira pakati kusindikiza pamwamba | 1. Malo osindikizira akuda2.Malo osindikizira awonongeka | 1. Chotsani dothi2.Konzaninso kapena sinthani |

| Kutayikira pa tsinde kulongedza | 1. Kupakira kukanikiza mphamvu sikukwanira2.Kulongedza katundu wowonongeka chifukwa cha ntchito yayitali 3.O-ring kwa stuffing bokosi ndi kulephera | 1. Limbani zomangira mofanana kuti zigwirizane ndi kulongedza2.Bwezerani kulongedza katundu

|

| Kutayikira pa kugwirizana valavu thupi ndi kumanzere - kumanja thupi | 1.Maboliti olumikizira amamanga mosagwirizana2.Kuwonongeka kwa nkhope ya flange 3. Gaskets zowonongeka | 1. Kumangika mofanana2.Konzani 3. Bwezerani ma gaskets |

| Chotsani valavu yamafuta | Zinyalala zili mkati mwa mavavu amafuta | Yambani ndi madzi oyeretsera pang'ono |

| Kuwononga valavu yamafuta | Ikani ndikusintha mafuta othandizira pambuyo poti payipi yachepetsa kuthamanga | |

| Kutaya valavu drainage | Kuwononga kusindikiza kwa valve yokhetsa | Kusindikiza kwa ma valve otayira kuyenera kufufuzidwa ndikutsukidwa kapena kusinthidwa mwachindunji.Ngati chawonongeka kwambiri, ma valve otayira ayenera kusinthidwa mwachindunji. |

| Gear box/actuator | Kulephera kwa bokosi la gear / actuator | Sinthani, kukonza kapena kusintha bokosi la gear ndi actuator molingana ndi bokosi la gear ndi ma actuator |

| Kuyendetsa mosasinthasintha kapena mpira sikutsegula kapena kutseka. | 1. The stuffing bokosi ndi kugwirizana chipangizo ndi skewed2.Tsinde ndi mbali zake zawonongeka kapena dothi. 3. Nthawi zambiri kutsegula ndi kutseka ndi dothi pamwamba pa mpira | 1. Sinthani kulongedza, kunyamula bokosi kapena chipangizo cholumikizira.2.Kutsegula, kukonza ndi kuchotsa zimbudzi 4.Open, yeretsani ndikuchotsa zimbudzi |

Zindikirani: Wothandizira ayenera kukhala ndi chidziwitso choyenera komanso chidziwitso chogwiritsa ntchito ma valve

Nthawi yotumiza: May-19-2022